Workers’ health is increasingly being monitored and regulated

Some companies have specialized in installing filtration systems for heavy equipment and vehicles operating in high-risk environment.

However, they still need to comply with rules and ensure that filters are compliant and properly used.

Issue :

Eliminate all health risks for heavy equipment operators by ensuring optimized use of built-in filters and prevent all risks of fraud (expired filters).

The challenge: Offer a built-in tracking solution that can actively prevent the operator from working if tracked data is non-compliant.

Our solution: A built-in automatic filter identification and use tracking system.

Solution :

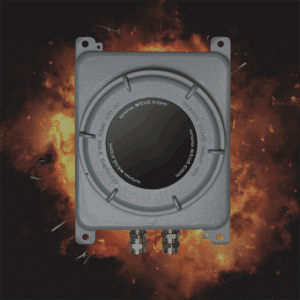

- A UHF tag

- Unit identification of filters and number of filtering hours embedded in their memories

- Built-in UHF reader

- Automatic check of filter presence and validity

- Built-in screen installed in the cab

- The operator can see the state of the filter system in real time

- In-cab alert system

Warning triggered or the equipment cannot be started if filters are missing/expired or there is a problem with the filter system.

Key benefits:

- Reliable health and safety protection process

- Operator autonomy for managing filters

- Increased productivity

Fewer vehicles out of service for filter non-conformity

Lien hub produits

/

Find your challenge

Every project starts with a challenge to overcome: securing access, upgrading infrastructure, or ensuring reliable identification… In this section, we help you connect real-world needs with the right solutions. Whatever the challenge, our technologies offer flexible, effective responses tailored to your specific context.